The condition of deck plating on an LNG (Liquefied Natural Gas) vessel during a voyage is of paramount importance to ensure the safety, structural integrity, and operational efficiency of the vessel. The deck plating forms the uppermost structural surface of the ship’s deck. Here are some key considerations regarding the condition of deck plating on an LNG vessel during a voyage:

- Corrosion: Deck plating is exposed to harsh marine environments, including saltwater, which can lead to corrosion over time. Regular inspection and maintenance are crucial to identify and address corrosion issues promptly.

- Structural Integrity: The deck plating provides support for various equipment, containers, and personnel on the vessel. Any damage or weakening of the plating could compromise the vessel’s structural integrity and overall safety.

- Impact and Loading: During the voyage, the deck may experience impacts from equipment handling, loading and unloading of cargo, and even heavy weather conditions. These factors can contribute to wear and tear on the deck plating.

- Welds and Joints: Deck plating is often joined together through welding, and the quality of these welds is essential for maintaining integrity. Cracks, fractures, or poor welds can lead to failures.

- Inspection: Regular inspection of the deck plating is essential to identify any signs of damage, corrosion, cracks, or other issues. Various non-destructive testing methods (e.g., ultrasonic testing, magnetic particle inspection) can be employed to assess the condition without causing further damage.

- Maintenance: Depending on the severity of the conditions and wear, maintenance activities such as sandblasting, repainting, or even replacing damaged sections of deck plating may be necessary.

- Safety: LNG vessels operate in challenging environments, and maintaining the condition of the deck plating is vital to ensure the safety of the crew, the cargo, and the environment. In the event of a leak or spill, the deck must be structurally sound to support emergency response activities.

- Environmental Considerations: LNG vessels operate in ecologically sensitive areas, and any potential deck-related incidents can have severe environmental consequences. Ensuring the integrity of the deck plating can help mitigate these risks.

- Regulations and Class Requirements: LNG vessels are subject to strict regulations and class requirements set by maritime authorities and classification societies. Compliance with these standards is essential for the vessel’s operational certification.

- Monitoring Systems: Many modern vessels are equipped with structural health monitoring systems that provide real-time data about the condition of various ship components, including deck plating. These systems can help identify problems early and enable timely interventions.

Maintaining the condition of deck plating on an LNG vessel during a voyage is crucial for safety, structural integrity, and compliance with maritime regulations. Regular inspection, maintenance, and adherence to industry standards are key practices to ensure the continued safe operation of the vessel.

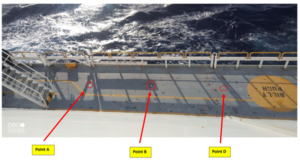

In a case of an LNG vessel which MOG Technologies recently had completed using SPS, excessive steel diminution with deep pitting and holes had occurred on the upper deck above tank requiring local steel reinstatement. The LNG vessel has the capacity of transporting 142,800 cubic metres of liquid gas and was between her voyages in Indonesia waters, an important factor when choosing the method of repair.

SPS Cold Work installation was used to deliver this permanent repair, reinstating the existing deck and creating a new composite section. Structural adhesive approved by classification societies was used to fit and join the steel components to form airtight cavities into which the elastomer core was injected. All steel components were prefabricated before shipping on-board for installation. This reduced the cost of the project, eliminated welding requirements, reduced time offshore for the installation team, which in turn, simplified project logistics. This design and process was evaluated and approved by ABS classification.

Unlike SPS, conventional in-situ repairs of this sort are slow and expensive and limit a vessel’s operating capacity. The structural steel reinstatement of the upper deck plating using SPS was carried out during anchorage by ship crews and MOG Technologies injection engineer. SPS enabled the LNG carrier to avoid going into shipyard, which took four days to complete.

Using the SPS Cold Work solution to reinstate the upper deck of plating of LNG vessel ensured 100% operational capacity was maintained throughout. Tank or void spaces below were unaffected or remained operational since no under deck scaffolding required in confined space and no tank cleaning was required. While the SPS Cold Work solution non-disruptive repair was completed much faster than a crop and renew repair, the process also eliminated fire risk which is an advantage especially for LNG carriers. With SPS technology, the reinstated deck plate is stronger than original design of the upper deck plating.

SPS Technology has had many projects on offshore and marine assets spanning 20 years. First SPS Cold Work solution was in 2005 when it was used to reinstate 1m² of the bottom shell in the oil cargo tank in 2005, whilst the unit remained on-station and in full operation in Equatorial Guinea. The use of SPS Cold Work has continued to reinstatement of side shell and transverse bulkhead in cargo tanks, offshore Gulf of Thailand and reinstatement of main deck above cargo tanks in Brazil and Ivory Coast offshore.

SPS provides the opportunity for operators to undertake repairs on-station with no impact on production and day-to-day operation. Parts are prefabricated on-shore in advance to cut project duration, POB (Personnel on Board), optimise repair quality and, most importantly, overall budget.

SPS removes the need for cofferdams and dive boats, scaffolding and all costs associated with crop and renewal. The SPS Cold Work process uses structural adhesive and bolts for fitting new steel components in place. The bolted connections transfer the full structural capacity across the joints. Once the SPS installation is complete, the composite panel, created through bonding the solid elastomer core to the top and bottom face plates, has strength in excess of the original plating. There is no upper limit on the size of an SPS Cold Work repair – the largest approved by ABS was in excess of 800m².

SPS is approved by all major Classification Societies.