Offshore Safety Assured

Quality Guaranteed

Permanent coldwork repair for offshore and maritime structures

with Sandwich Plate System (SPS) technology.

An Authorised Installer of SPS Technology Coldwork Solutions

Approved by Majority of IACS Societies

Approved by Majority of IACS Societies

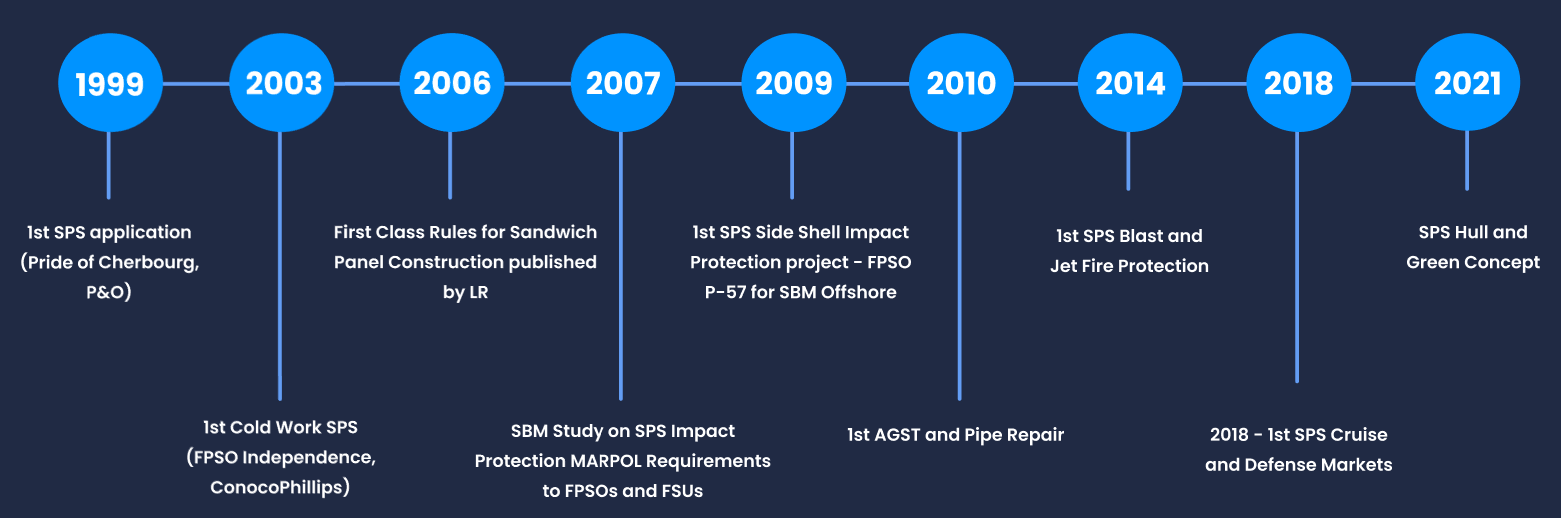

About SPS Technology Coldwork Solutions

Requires up to 90% less labour and 56% less steel than crop and renew technique.

Up to 11x less expensive and 3x faster than traditional steel crop and renewal.

Used in over 500 projects covering 300,000m of various marine and offshore applications.

Requires up to 90% less labour and 56% less steel than crop and renew technique.

Up to 11x less expensive and 3x faster than traditional steel crop and renewal.

Used in over 500 projects covering 300,000m of various marine and offshore applications.

About Us

Mission

To provide cold repair technology and solution, cost-effective, safe and uncompromised quality services.

Vision

To become Asia’s top solution provider for structural integrity in Marine and Offshore Industry.

Mission

To provide cold repair technology and solution, cost-effective, safe and uncompromised quality services.

Vision

To become Asia’s top solution provider for structural integrity in Marine and Offshore Industry.

What we do

At MOG Technologies, we focus on providing trustworthy

offshore repair solutions that stand the test of time.

As a proven product, MOG Technologies has chosen SPS

as a key solution to offer robust cold work repair and

accelerate growth for offshore and maritime businesses.

Our trusted partners

Sandwich Plate System Technology

PTT Exploration and Production Public Company Limited

Pan Mechanic Engineering Co. Ltd

Why choose MOG Technologies?

Ensure greater safety

Hot works eliminated. Drastically improving safety on ships and offshore assets especially storage, production, transportation of flammable cargo, and materials.

Save time

Pre-welded materials, fast delivery, and onboard installation reduces downtime and assures quick completion.

Ensure greater safety

Fixed costs for materials and installation mean transparent pricing and no hidden fees.

Less Personnel Onboard and Shorter Schedule

4 weeks

Submission of design specifications for the approval of materials, documentation, and installation by the respective classification society.

6 weeks

Fabrication of materials onshore via pre-welding and chemical injection preparation. Logistics are then delivered to vessels or offshore structures.

2 weeks

Surface preparation and installation followed by SPS installation, chemical injection, and quality assurance by certified technicians from MOG Technologies.

4 weeks

Submission of design specifications for the approval of materials, documentation, and installation by the respective classification society.

6 weeks

Fabrication of materials onshore via pre-welding and chemical injection preparation. Logistics are then delivered to vessels or offshore structures.

2 weeks

Surface preparation and installation followed by SPS installation, chemical injection, and quality assurance by certified technicians from MOG Technologies.

Popular Coldwork Applications

Bulkhead Plate, Shell Plates, Web and Longitudinal Repair

The traditional repair would require hotwork, diver and cofferdam.

There was no need for any hot work in tank, cutting through of bulkheads and side shell hull and time-costly leakage tests, saving the FSO precious man hours, giving them a reliable yet competitive service.

Bulkhead Plate, Shell Plates, Web and Longitudinal Repair

The traditional repair would require hotwork, diver and cofferdam.

There was no need for any hot work in tank, cutting through of bulkheads and side shell hull and time-costly leakage tests, saving the FSO precious man hours, giving them a reliable yet competitive service.

Bottom Plate and Tank Top Plate Repairs

A Floating Production Storage and Offloading (FPSO) vessel, required reinstatement work within the inner bottom of a cargo oil tank.

As a result, FPSO experienced zero downtime, and avoided massive opportunity costs as the crude oil tank would need to be cleaned and production would be stopped.

Frequently Asked Questions

1. Duplicate

Step 2 – Fitting of Perimeter Bars Flat bars of thickness equal to the nominal elastomer core thickness are fitted to create boundaries for the injection cavities. These are welded or adhered to the existing structure. In some cases, the bars may be fitted before blasting the surface of the existing plating.

1. What are SPS Processes?

Step 2 – Fitting of Perimeter Bars Flat bars of thickness equal to the nominal elastomer core thickness are fitted to create boundaries for the injection cavities. These are welded or adhered to the existing structure. In some cases, the bars may be fitted before blasting the surface of the existing plating.

2. Is SPS a permanent solution approved by classification society?

Yes. SPS is a permanent solution approved by all major IACS societies.

3. Is SPS similar to doublers?

No. SPS is totally different with doubler. Doublers do not strengthen the corroded plating but SPS does.

4. Can SPS be done without hotwork?

Yes, majority of SPS application for oil and gas environment is done without involvement of hotwork

5. What are the information required for SPS?

Generally, SPS will require inspection report like Ultrasonic thickness measurement and structural drawing of the area to be repair